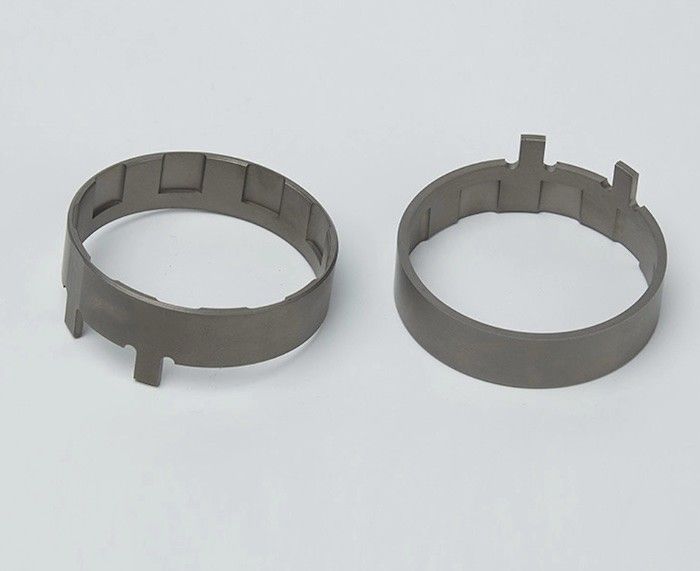

This product requires the use of slow wire cutting machine and mirror spark machine to achieve precise dimensional requirements and a RA0.8 finish. The products are used in occasions where wear resistance is required. We use chemical nitriding method to carry out surface treatment on the products to increase the wear resistance of the products. In recent years, our company has introduced a large number of precision slow wire cutting machines and EDM (mirror sparking machines) from Japan, Taiwan and other places. The production accuracy is reliable and the efficiency is high. It has achieved a very good reputation in the industry, and we look forward to serving more customers.

Product Information:

| Manufacturer |

Hua Bao |

| Product Name |

Machined Metal Parts- Gears |

| Industry Standards |

DIN, JIS, AISI, GB |

| Design Tools |

UG, ProE, Auto CAD, Solidworks, etc |

| Material |

DC53 |

| Hardness |

HRC58~62 |

| Quality Control |

Hardness Tester, Caliper, Altimeter, CMM, Projector, Quadratic Element |

| Processing Machines |

Slow Wire-Cutting Machine, Mirror Spark Machine |

| Surface Treatment |

Nitriding |

| Other Service |

ODM and OEM, Customized Specification, One to One Communication, Free Samples |

| Order Process |

Customer inquiries (provide 2D or 3D drawing)→ Hua Bao provides quotes and lead time→Orders released by customer→ 50% advanced

payment→ Arrange production→QC pass→ Packing and shipping after receiving balance payment.

|

In recent years, we have introduced many high-precision processing machines and inspection instruments. Such as:

Processing Machines: Machining Centers, NC Lathes, Wire-cutting Machines and Mirror Spark Machines, Optical Grinding Machines and NC Grinders.

Inspection Instruments: Coordinate Measuring Machines, Quadratic Elements, Projectors and Altimeters, Rockwell Hardness Tester.

Our devices are equipped according to the highest international standards. Complete processing and inspection equipment plus the best quality-mind are our guarantee for the excellent quality and service for customers.

Pros of Hua Bao Machined Metal Parts:

1. Using high-end machines to process to meet accuracy.

2. Integrated inspection instruments to guarantee quality before shipping.

3. Raw materials and heat treatment are provided by best manufacturers, such as ASSAB, TOKAI, etc.

4. Most competitive price for each order.

Why Choose Us?

1. Best product quality and most competitive price.

2. Experienced technicians are in production.

3. High-end processing machines and inspection instruments.

4. Customized designs and production.

5. Excellent pre-sale and after-sale service.

Core Value and Company Culture:

Business Philosophy:

1. Quality is the soul of an enterprise.

2. Competitive price is our advantage.

3. Enthusiastic service is our tenet.

4. Innovation is our eternal pursuit

Quality Objectives:

1. Sample acceptance rate reaches 100%.

2. The qualified rate of finished products reaches 100%

3. Punctual delivery rate reaches 100%

Our Mission:

1.Strengthen management and continuously enhance satisfaction for customers, investors, suppliers and employees.

2. Enhance innovation capacity and contribute to sustainable development.

Hua Bao Promise:

1. Provide the detailed production schedule for each order.

2. Offering production status with video and photos for each component.

3. Manufacture the parts base on customers' drawings to meet the quality requirements and industry standard.

4. Over 99% orders can meet the lead time requirement.

5. Respond to the enquiry within 24 hours and offer the quotation within 48 hours.

6. Using the first-rank raw materials which also can be traced.

7. Provide the most competitive price with the high quality and service standard.

8. The most reasonable packing scheme for all products.

FAQ:

Q1: What are the types of EDM process?

A: Electric discharge machining can be divided into three common types, Die sinking EDM, Wire EDM and hole drilling EDM.

Die sinking EDM.

Wire EDM.

Hole drilling EDM.

Q2: What does EDM stand for in machining?

A: Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges.

Q3: Which material is used for EDM process?

A: Electrodes that are generally used in EDM process are copper, graphite, copper tungsten, silver tungsten, tungsten carbide, brass.

Q4: What is application of EDM?

A: The EDM process is most widely used by the mold-making, tool, and die industries, but is becoming a common method of making prototype and production parts, especially in the aerospace, automobile and electronics industries in which production quantities are relatively low.

Q5: What are the advantages of EDM?

A: Creates complex shapes that would otherwise be difficult to produce with conventional cutting tools. Cuts extremely hard, challenging and exotic materials to very close tolerances for high precision mechanical components.

Q6: What is the difference between EDM and wire EDM?

A: Conventional EDM cannot produce narrower angles or more complex patterns, while wire-cut EDM can be performed. A more precise cutting process allows for more complex cuts. The wire EDM machine is capable of cutting a metal thickness of about 0.004 inches.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!