Why choose us?

1. We are a professional manufacturer specializing in manufacturing various metal parts, including CNC precision automatic lathe machined parts, automatic lathe parts, milling machined parts, wire cutting machined parts etc.

2. With experienced technical engineers and modern inspection equipment, our factory can help you to lower cost at the moment of worldwide financial crisis.

3. We are committed to focusing on the client's demand and satisfaction, and to providing high quality products at competitive prices according to your drawings or samples. Special parts for your special needs!

4. Our strong R&D and QC department can control the products to meet your strict requirment, 100% inspection on critical dimensions with high accuracy +/-0.01-0.005mm.

5. Factory direct price and on time delivery.

6. Small quantity acceptable.

7. Free samples available.

8. OEM workable.

FAQ:

Q1: What is core and cavity insert?

A: The core and cavity are the two halves of the mold where the hot molten plastic material is injected into the core and cavity and the gap between the core and cavity is filled with the hot molten material during the injection molding process and then hardened into the final shape.

Q2: Why core is used in mold cavity?

A: A core is a device used in casting and moulding processes to produce internal cavities and reentrant angles (an interior angle that is greater than 180°). The core is normally a disposable item that is destroyed to get it out of the piece.

Q3: What are inserts in injection molding?

A: Insert injection molding is the process of molding or forming plastic parts around other, non-plastic parts, or inserts. The inserted component is most commonly a simple object, such as a thread or rod, but in some cases, inserts can be as complex as a battery or motor.

Q4: What is the difference between core and cavity?

A: The core is the male part which forms the internal shape of molding. The cavity is the female part which forms external shape of molding.

Q5: What are the different types of cooling cavity inserts?

A: Injection Molding Cooling Types and Layout:

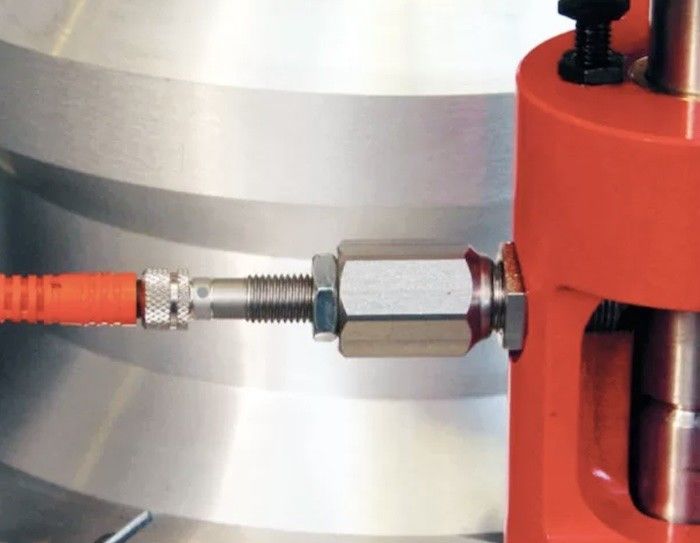

1. Cooling line in core /cavity inserts.

2. Connecting cooling line between mold plates and inserts.

3. Different cooling line type.

4. Cooling tower.

5. Cooling line in lifter.

6. Cooling line in slider.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!