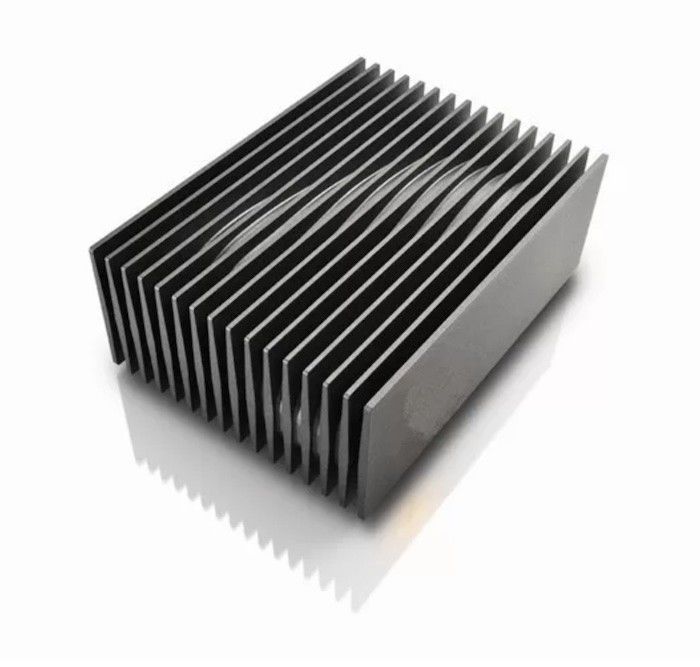

Anodized CNC Aluminium Parts , LED Bulb Light Stamped / Extruded Heat Sink

Quick Detail:

1. Material: Aluminum alloy as demand

2. Surface Finished: Anodised & Sandblasting

3. Process: Mill finish, Anodized, Powder coated, Electro phoresis

4. Tolerance: 0.02mm

Description:

Forging can produce round and other non-linear shapes that are preferred for LED applications.

The forge process uses high pressure to form the material and provides control over the grain structure to provide superior thermal performance.

LED’s are generally convection cooled and our forged pin fin arrays provide the best possible thermal performance in ambient environments.

Heat sinks can be forged in either aluminum or copper.

Sizes range from 5 mm diameter to 100mm and shapes can be almost any shape you need.

Business Cope:

Extruded heat sinks, Stamped heat sinks, Bonded fin heat sinks, Folded fin heat sinks, Active Heat Sinks, Forged heat sinks, Swaged heat sinks, Single Fin assembly Heat Sinks, Skived Heat Sinks.

Which Aluminium Profiles We could supply

Alloy: 1060, 2024, 3003, 5005, 5056, 6063, 6061, 6082, 6060, 6005, 6A02

Temper: T3, T4, T5, T6

Finish: Mill finish, Anodized, Powder coated, Electro phoresis, Wooden grain.

Extrude size: 10mm-250mm

Technology Supports

Engineering design

Autocad drawing

Aluminium profiles deeply processing: cutting, punching, drilling, milling, and fabricating.

Usage:

Industry Aluminum profile used in cars, trains machinery, electronics, medical and other industrial filed .

In terms of hardware, machinery, electro mechanical parts, solar PV products, aluminum frames as important auxiliary materials. We also have aluminum profiles for radiators, fitness machinery, buildings, lighting instrument, windpipes, oil pipelines, for instance.

Advance:

| Our Advance |

| 1. Direct from factory |

| 2. Low(1-2%)scrap rate |

| 3. All kinds of metal&plastic material is available |

| 4. High Tolerance: +/- 0.02mm(Metal shaft), +/-0.03mm(plastic) |

| 5. 100% inspection(offer QC report) |

| 6. Sample is available |

| 7. Short lead time (5-20 days). |

| 8. One-stop customized service |

We major on:

| 1. Aluminum Precision Product |

2. Extrusion/ Profile |

| 3. Hardware |

4. Injection molding |

| 5. Aluminum Frame |

6. Furniture Part |

| 7. Aluminum Office and Living Product |

8. CNC Precision Milling Part |

| 9. CNC Precision Turning Part |

10. Punch& Stamping& Stretching& Riveting& Assembly |

| 11. Die Casting& Welding& Forging& Bending Part |

12. Medical Aluminum Part |

| 13. Aluminum Pipe |

14. Large Cross-section/ High Challenge Heat Sink |

| 15. Mechanical Industrial product/ Auto Part |

16. LED Aluminum Accessory |

| 17. Mold Design and Manufacture |

18. Surface treatment |

Specifications:

| Material |

Aluminium alloy; 6063, 6061, 6082, 6005, T5, T6, |

| Section Shapes |

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot or other complicated shapes by custom design. |

| Surface treating |

Anodic Oxidation, Powder Spraying, Eletrophoretic Coating, Wood-grain Transfer, Fluorocarbon Spraying, Sand blast, Polished, Brushed |

| Application |

- for Window and door frames

- for LED lighting Frame

- for Building curtain glass walls

- for Motor Shell

- for Hook of LED Stage lighting

- for Industry assembly lines equipment.

- for Heat sinks, such as: LED lighting, Car Audio Shell, High-power LED Street lighting, LED tunnel lighting and so on.

- other by custom design size and dimension |

| Production lines |

5 melting and casting production lines

6 extruding production lines(from 600tons to 5000tons and meet different customer's demands)

2 anodizing and electrophresis production lines

2 powder coating production lines

4 wooden grain production lines

2 heat insulation broken bridge production lines

2 wiredrawing and polishing production lines |

| Characteristic Services |

-OEM Service.

-Design according to the customers' requirements.

-More years' professional experience in research, manufacturing

-Our modern deep processing center can provide machining such as Cutting, punching, drilling, CNC Machining etc. |

| Quality Control |

We operate the most strict quality control system, the detection is from the material, production process, To final product, and ensure the product quality and traceability. |

| Process |

Die design →Die making →Smelting& alloying →QC →Extruding →Cutting →Heat Treatment →QC →Surface treatment →QC →Welding →Packing →QC →Shipping →After Sale Service |

| Standard |

GB5237-2008 equal to EN12020-1.2(2001) |

| Payment |

T/T: 30% for deposit, the balance will be paid before or after shipment |

| Packaging Detail |

-Inside: Packed with plastic film to protect each piece

-Outside: Wrap to be bundles by waterproof craft paper or EPE film. Customized request available |

| Lead Time |

-Die Developing and Sample testing: 10-12 days.

-Mass Production: 15-25days. It depend on your quantity. |

Applications:

|

Cars

Bikes

Aircraft

Musical instruments

Watercraft

Optical devices

Sensors

Models

|

Nameplates

Electronic devices

Enclosures

Clocks

Machinery

Engines

Furniture

|

Jewelry

Jigs

Telecom

Lighting

Medical devices

Photographic devices

|

Robots

Sculptures

Sound equipment

Sporting equipment

Tooling

Toys

and more

|

Competitive Advantage:

Competitive price

Quality approvals

Guarantee and warranty

Small orders are accepted

Best service and prompt delivery

Good products performance

International approvals

Manuafacturer rich experience

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!